With our pre-assembled, labeled strand sets:

Cabinet building up to 80 % faster

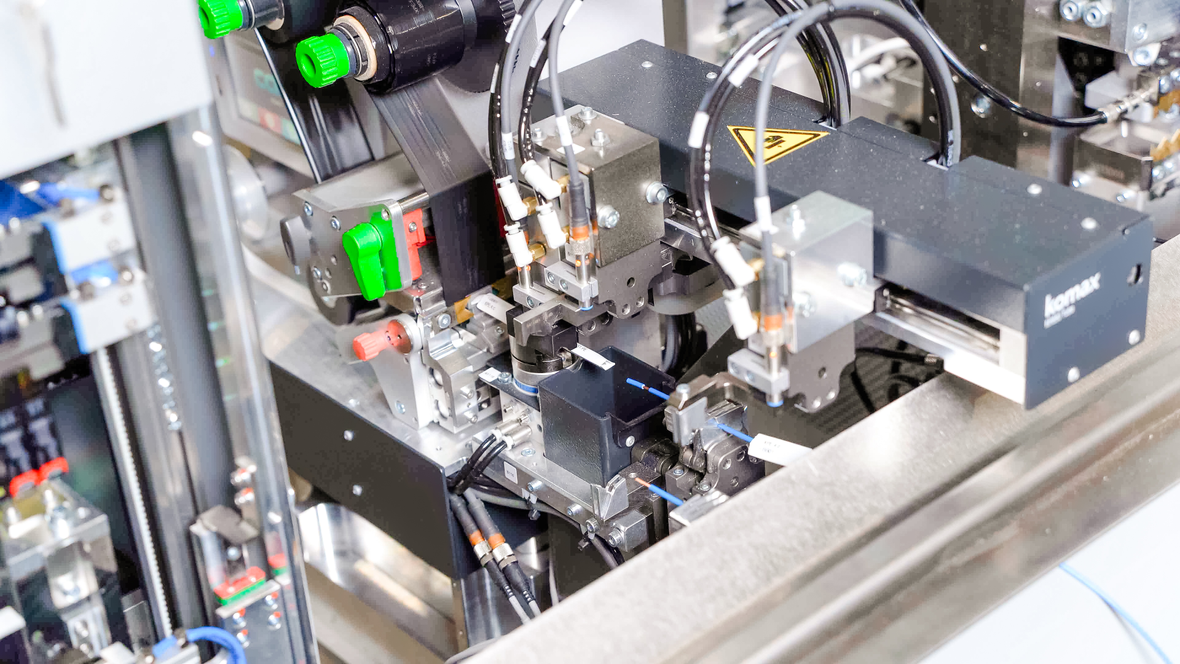

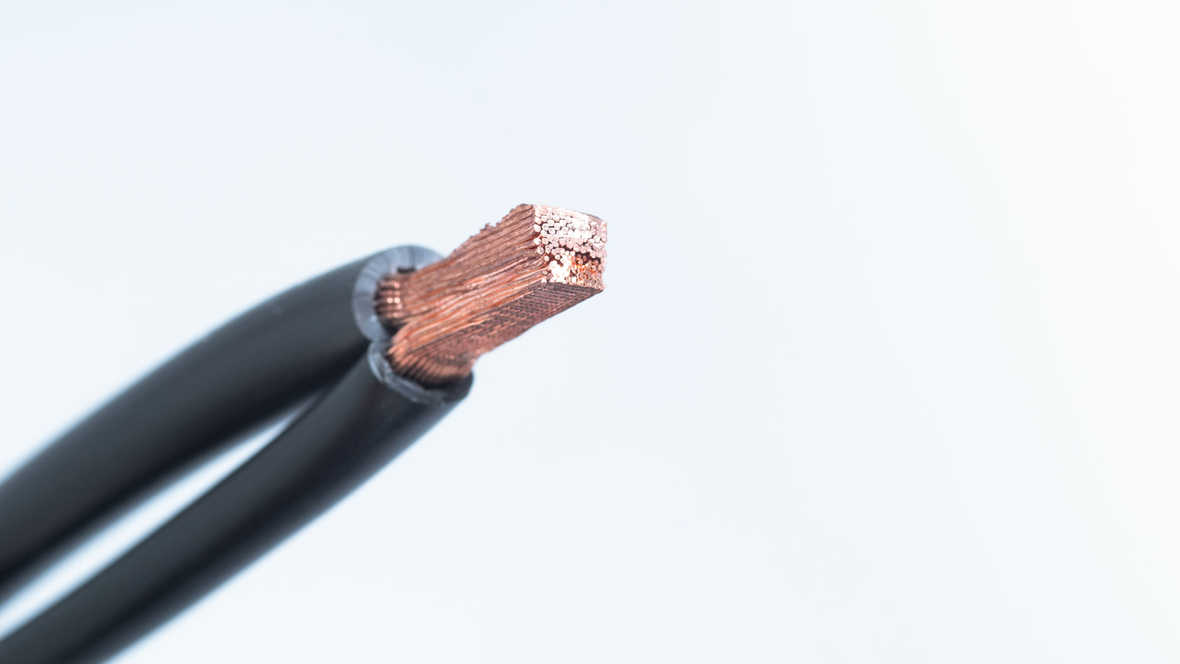

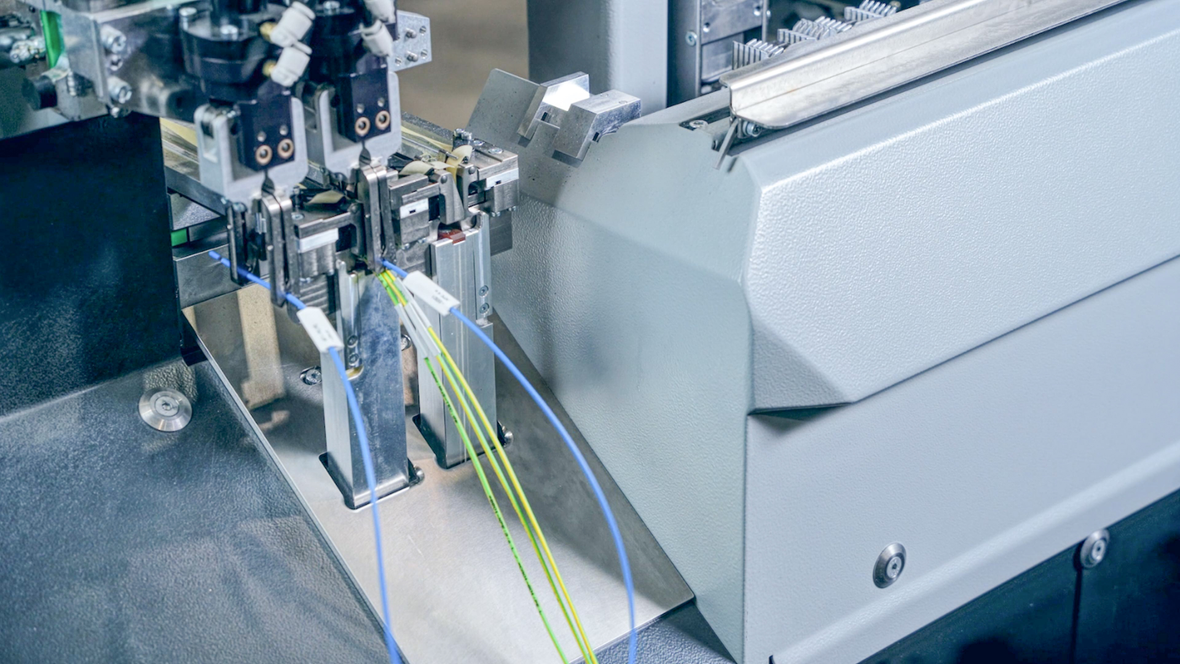

Fully automated solutions for precise wire harness production: Cutting, stripping, ultrasonic compaction or crimping, printing, and bundling in the assembly sequence.

View Our ServicesWUSTEC offers round and sequential wire bundles for control cabinet construction. For this purpose, we offer precise processing of strands to your specific needs. Cutting, stripping, ultrasonic compaction, crimping, printing, and bundling the strands in the assembly sequence saves time and the need for specialized personnel in control cabinet construction. Your employees no longer require a wiring diagram, as start and end points are printed on each insulated conductor.

In addition, we offer ready-made stranded wires for mechanical engineering, distributor construction, or other applications where the same wires are required in small or large quantities. You select the corresponding wires, we handle the precision wire processing.

This pays off:

From a quantity of 1

- The Wiremaster: The fastest bundling software in the world.Now in the cloud. Simply log in. Upload the wire list. And you’re done!

- Bundle, label, and order wire lists fully automatically.Always the right bundling and labeling thanks to individual layouts

- Receive preassembled wire sets. Ready!Wire the control cabinet “without tools,” without waste, and at a fixed price

Our prefabricated and printed sequential and round bundles allow you to wire your control cabinets up to 80% faster, error-free, and without strand waste.

Our Service Your BenefitsSave time during wiring

Production and planning security

High cable availability

If you could write on the cables where they belong in the control cabinet, then even a semiskilled worker could wire the cabinet. And all in half the time.

Ralph Schmid, CEO and Founder

In the year 2000, Ralph Schmid, as an employed electrical systems engineer, asked himself whether it would be quicker and easier to wire a control cabinet if all the wiring information could be printed on the wire. Shortly after, he bought a prototype machine and printed the first strands in a rented garage.

In the meantime, WUSTEC’s range of services includes not only simple labeling and assembly, but also simplified data preparation with our Wiremaster cloud software. This has made it possible to reduce even more sources of error.